EPCB Boiler es un fabricante profesional de calderas en China. Centrado en la producción y venta de calderas industriales durante 68 años. Nuestros principales productos son calderas de carbón, calderas de gasóleo, calderas de biomasa, calderas eléctricas y calderas de centrales eléctricas.

-

Caldera de carbónr

-

Caldera Agua Caliente

Caldera Agua Caliente

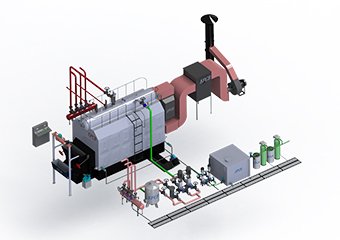

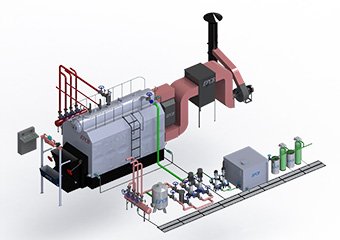

Caldera Agua CalienteLa serie de calderas de agua caliente de carbón EPCB, con las ventajas de combustión total, alta eficiencia térmica y menos emisiones contaminantes, etc., ha ganado muchas certificaciones de estándares mundiales y ha sido reconocida por la mayoría de los usuarios.

More >> -

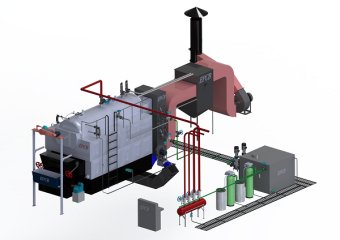

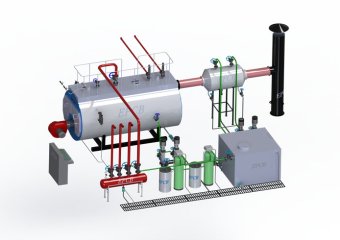

Caldera de Vapor

Caldera de Vapor

Caldera de VaporLa serie de calderas de vapor de carbón EPCB adopta un nuevo diseño de caldera, con una gran superficie de calentamiento. La tecnología avanzada de separación de vapor y agua, el economizador de alta eficiencia y otras máquinas auxiliares se adoptan para ahorrar energía y proteger el medio ambiente. La eficiencia térmica más alta puede alcanzar el 84,61%.

More >> -

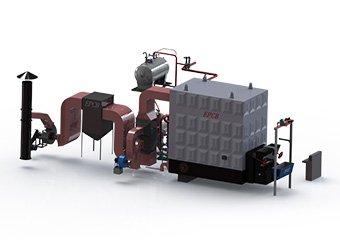

Caldera Aceite Térmico

Caldera Aceite Térmico

Caldera Aceite TérmicoSerie de calderas de aceite térmico de carbón EPCB, nueva estructura, combustión completa, calentamiento rápido, menos pérdida de calor, el sistema de control automático puede controlar mejor el funcionamiento de la caldera. Puede ahorrar al menos un 3% del costo de combustible cada año.

More >>

-

Caldera Agua Caliente

-

Caldera Gasoil / Gas

-

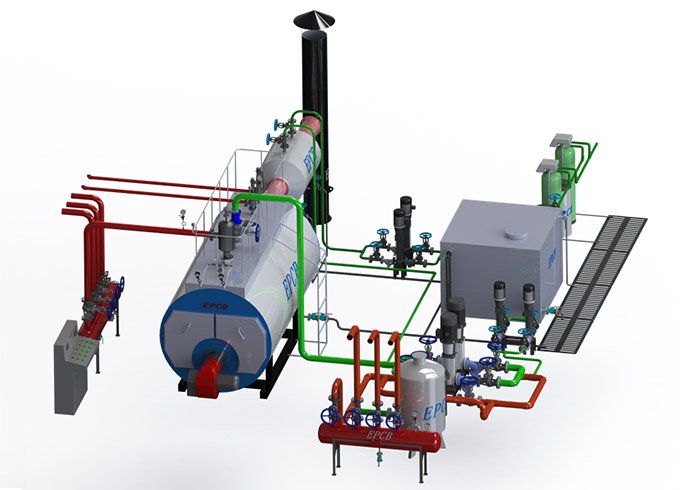

Caldera Agua Caliente

Caldera Agua Caliente

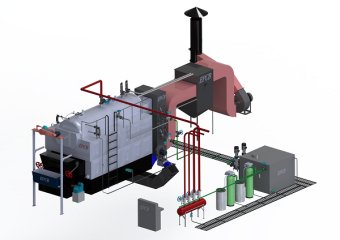

Caldera Agua CalienteLa serie de calderas de agua caliente de gas / petróleo EPCB, equipada con quemador importado original, combina el horno corrugado y el tubo de humos roscado a la perfección, aumenta en gran medida el área de calefacción, equipado con equipos de ahorro de energía de alto nivel, la eficiencia térmica de la caldera puede alcanzar más del 96%.

More >> -

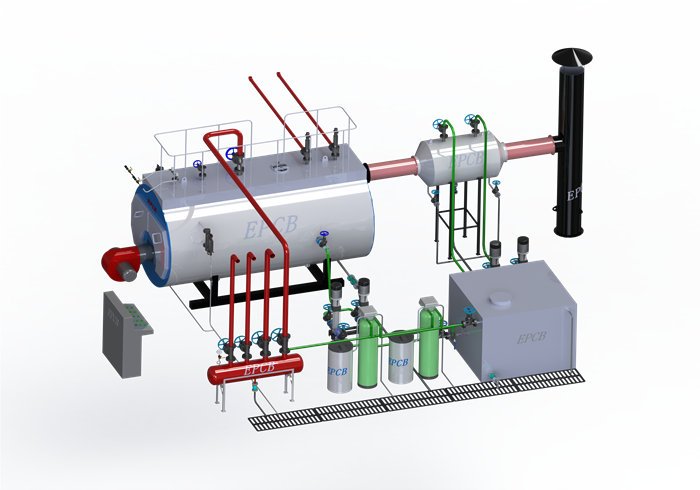

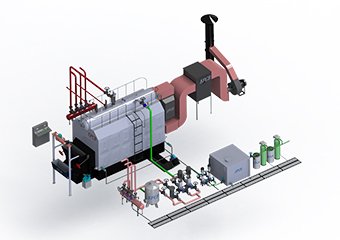

Caldera Vapor

Caldera Vapor

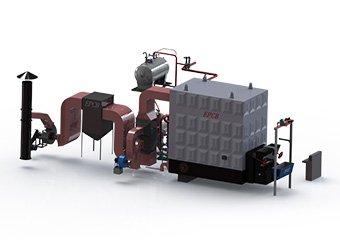

Caldera VaporLa caldera de vapor EPCB de gasóleo / gas, con estructura de respaldo húmedo de 3 pasadas, equipada con sistema de control automático, es fácil de operar, ahorra completamente los costos de mano de obra, instala un economizador de alta eficiencia, ahorra costos de combustible y se usa ampliamente en textiles e impresión y teñido, industria alimentaria, química, medicina y otras industrias.

More >> -

Caldera de aceite térmico

Caldera de aceite térmico

Caldera de aceite térmicoEPCB oil/gas thermal oil boiler, using imported Italian burner, burning more fully; The internal structure of the boiler with high heat transfer efficiency can raise the temperature more quickly. Adequate heating surface, small heat loss, complete testing instruments, with a safe and reliable, simple operation, wide application industry and other characteristics.

More >>

-

Caldera Agua Caliente

-

Caldera de biomasa

-

Caldera de agua caliente

Caldera de agua caliente

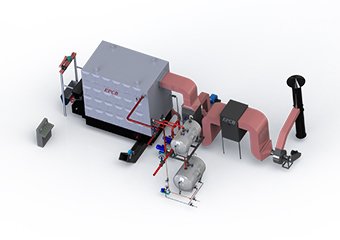

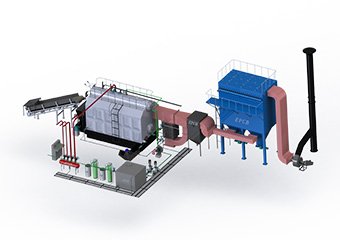

Caldera de agua calienteLa serie de calderas de agua caliente alimentadas con biomasa EPCB puede utilizar una variedad de combustibles de biomasa y quemarse completamente. La estructura razonable de la caldera y la disposición de la superficie de calentamiento pueden mejorar efectivamente la eficiencia térmica de la caldera. Ahora se usa ampliamente en calefacción, baño, lavandería y otro campo.s!

More >> -

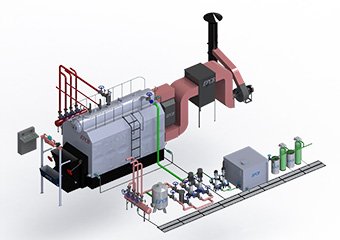

Caldera de vapor

Caldera de vapor

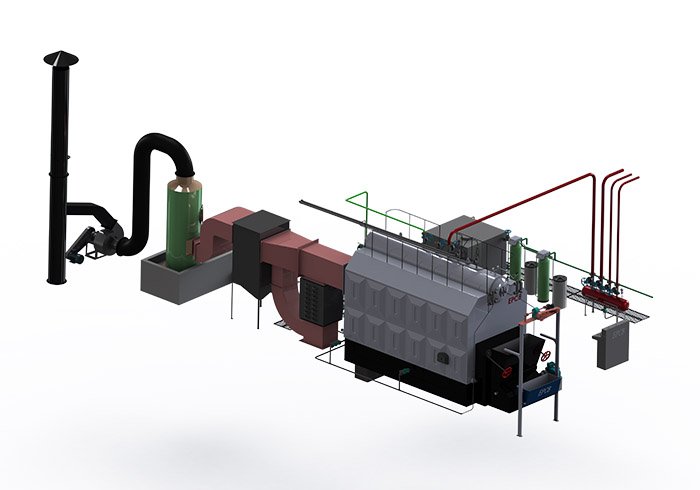

Caldera de vaporLa serie de calderas de vapor de biomasa EPCB adopta tubos de humos roscados con alta eficiencia de transferencia de calor, estructura de caldera de tres pasos, circuito de circulación de agua razonable, diseño de arco de radiación fuerte, etc. para hacer que la caldera sea más eficiente, más ahorradora de energía y más ecológica .

More >> -

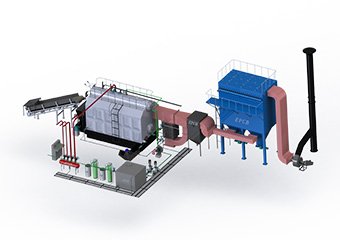

Caldera de aceite térmico

Caldera de aceite térmico

Caldera de aceite térmicoLa serie de calderas de aceite térmico de biomasa EPCB tiene una disposición razonable de la superficie de calentamiento por radiación y la superficie de calentamiento por convección, mayor eficiencia de transferencia de calor y mayor vida útil de las calderas. La caldera adopta una estructura de bobina de tres pasos, calefacción de ciclo cerrado, estructura compacta, alto grado de ensamblaje, más segura de usar.

More >>

-

Caldera de agua caliente

-

Caldera electrica

-

Caldera de agua caliente

Caldera de agua caliente

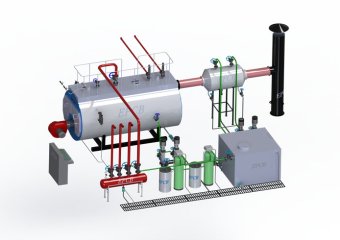

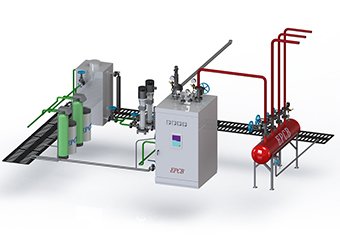

Caldera de agua calienteLa caldera de agua caliente eléctrica es un tipo de equipo mecánico que utiliza energía eléctrica como energía y calentador eléctrico tubular de metal para calentar el agua, de modo que la energía eléctrica se puede convertir directamente en energía térmica para producir agua caliente. Es ampliamente utilizado en hoteles, casas, lavanderías, piscinas, hospitales y otros lugares que requieren suministro de calefacción.

More >> -

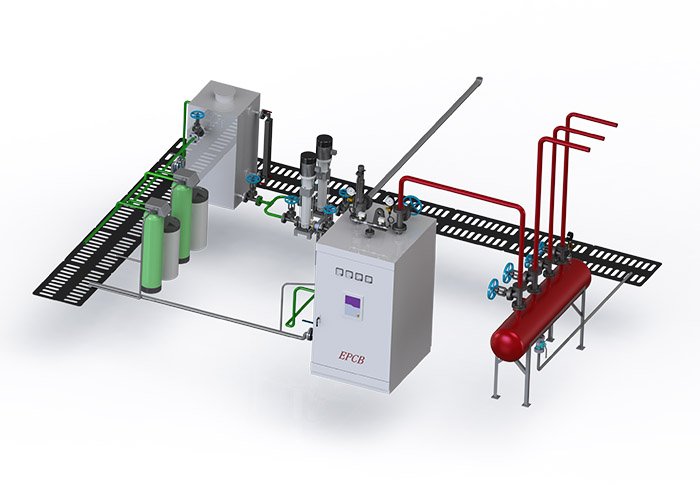

Caldera de vapor

Caldera de vapor

Caldera de vaporLa caldera de vapor eléctrica es un nuevo tipo de equipo de calefacción eléctrica que convierte la energía eléctrica en energía térmica. También se fabrica de acuerdo con las normas de supervisión de seguridad de calderas y los estándares de diseño de la industria de calderas. Tiene las ventajas de alta inteligencia, calentamiento rápido, alta eficiencia térmica, sin ruido, sin contaminación, etc.

More >> -

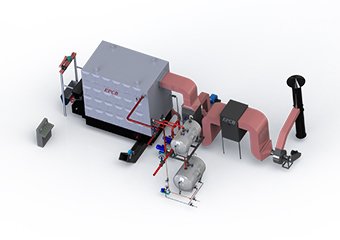

Caldera de aceite térmico

Caldera de aceite térmico

Caldera de aceite térmicoLa caldera de aceite térmico de calefacción eléctrica EPCB es un tipo de equipo de suministro de calor de alta eficiencia, que toma la electricidad como fuente de calor, el aceite térmico como portador de calor, utiliza una bomba de aceite de circulación de alta temperatura para llevar a cabo la circulación forzada de fase líquida del aceite térmico, transfiere energía térmica al equipo y luego regresa a la caldera para recalentamiento después de que se haya liberado parte de la energía térmica.

More >>

-

Caldera de agua caliente

- Caso exitoso

- Soluciones calderas

- Accesorios y repuestos